The objective for CBD harvest 2021 was to design, engineer, and fabricate a prototype machine and process for large scale hemp harvesting of biomass for CBD. The basic requirements were to design a continuous flow process tailored to capture a fresh (live) trichome concentrate with a throughput of 10,000 lbs of fresh biomass.

The process utilizes liquid nitrogen to flash freeze the hemp biomass and through a continuous tumbling process, the machine separates the frozen trichomes from the frozen biomass. The whole separation process is contained in an enclosed reefer trailer to maintain temperatures below -25˚C at all times. The process can stabilize the temperature in the reefer between -25˚C to – 75˚C for various trichome separation requirements.

Using liquid nitrogen, preserves the plant’s chemical compounds such as CBD and terpenes, which the process uses. Current industry standard drying methods result in contamination from mold and therefore decreases the value of the crop; adding heat to the process also breaks down the terpenes.

The developed process significantly reduces the volume of biomass going for further extraction such as crude oil or distillate, therefore enabling the extraction process to be more efficient and reduce the cost for the extractor by using less solvent extraction fluid.

During 2021 harvest a test plot of 200 acres of CBD hemp was utilized, 160 acres of Abound industrial hemp and 40 acres of a female Cherry Blossom hemp grow. The harvesting method that was utilized was capable of harvesting 45 acres per day with an average 1,250 biomass per acre and 1,000 lbs hemp grain per acre. The trichome separation process was able to produce 6,300 lbs of fresh (live) trichome concentrate with a CBD potency of close to 10%. The CBD potency can vary based on the mesh applied to the tumbler. During CBD harvest 2021 a 250 micron mesh was applied. For example, if higher CBD concentration is required, installing a finer mesh (e.g. 120 – 150 micron) could yield those higher results. The mesh is easily removable and depends on the final powder product requirements of the customer.

The below pictures illustrate the whole process from harvesting the hemp in field, all the way to producing the final fresh (live) concentrate.

Table of Contents

- Harvesting……………………………………………………………………………………………………………………………….. 3

- Unloading Hemp Grain and Hemp Biomass from Combine into Wagons………………………………………….. 5

- Unloading Biomass and conveying into the LN2 trichome separator…………………………………………………. 6

- CBD biomass flash freezing and submersion in LN2………………………………………………………………………. 7

- Separation of trichomes in enclosed Trichome Separator………………………………………………………………. 8

- Collecting of Trichomes……………………………………………………………………………………………………………. 12

- Discarding of biomass waste material………………………………………………………………………………………… 13

Harvesting

- Harvesting industrial hemp and female hemp grow with a S690 combine with a pull behind wagon to capture the CBD biomass

|

|

|

|

|

| Figure 1-3: Blower unit attachment blows biomass into wagon behind combine | Figure 1-4: Biomass stripped fiber left in the field |

Unloading Hemp Grain and Hemp Biomass from Combine into Wagons

- The hemp grain gets unloaded into one wagon and the CBD biomass into another. The hemp grain gets delivered to the farm for storage The CBD biomass is being delivered to the hemp site for further processing

|

|

|

Unloading Biomass and conveying into the LN2 trichome separator

- The CBD biomass gets unloaded at the hemp site on a cement pad. With a tractor bucket the biomass was loaded into a vertical mixer. A vertical mixer equipped with a scale system was utilized as a buffer to ensure continuous flow and measure throughput. Two additional conveyors were implemented into the process to be able to conveyor the biomass into the LN2 trichome separator

|

|

|

CBD biomass flash freezing and submersion in LN2

- Fresh CBD biomass is being conveyed into the transfer hopper where the biomass is being flash frozen and submersed in liquid nitrogen

|

|

|

Separation of trichomes in enclosed Trichome Separator

- The trichome separator consists of an industrial built, stainless steel sifting tumbler, able to process up to 10,000 lbs/hr of wet biomass

- Trichomes are being separated through a continuous flow tumbling and sifting process at up to -75˚C in the enclosed reefer trailer.

Figure 5-1: Transfer Auger feeding into Separator

- Illustration below shows the perforated tumber without the fine mesh and enclosure being installed

Figure 5-2: Perforated Tumblers

- Each perforated tumbler has a fine mesh installed on the outside. Through the tumbling action the trichomes get separated from the biomass and fall through the mesh

Figure 5-3: Mesh installed on tumblers

- Figure 5-4 below shows the area where the trichomes get collected once they fall through the sifting mesh

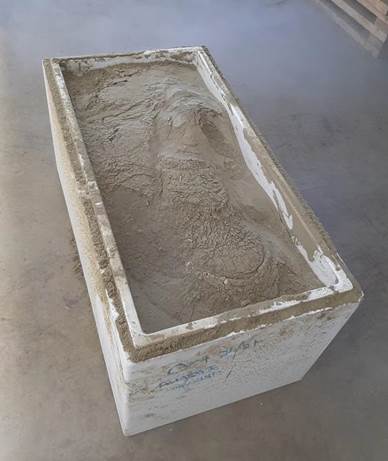

- The extraction auger conveys the captured trichomes to the opening in the machine for final collection in styrofoam boxes

Figure 5-4: Extraction auger beneath tumblers

Collecting of Trichomes

- Collected trichomes are being stored in styrofoam boxes in a separate reefer trailer at -25˚C to be delivered to the extraction facility for further processing

- On average 35 lbs per acre yield of 10% CBD kief was achieved

|

|

|

Discarding of biomass waste material

- The remaining biomass waste material was utilized as fertilizer in the neighbouring field

|

|

|

Figure 1-2: Harvesting Cherry Blossom, female grow hemp variety

Figure 1-2: Harvesting Cherry Blossom, female grow hemp variety